CLICK ME !

Abrevieri & informatii generale

Abrevieri & informatii generale (RO) – http://www.e-automobile.ro/abrevieri.html

Motor Diesel – https://en.wikipedia.org/wiki/Diesel_engine

Motor benzina (Otto) – https://en.wikipedia.org/wiki/Otto_engine

Cuplu vs Putere: http://www.e-automobile.ro/categorie-dinamica/6-cuplu-putere-motor.html

Tuning – https://en.wikipedia.org/wiki/Engine_tuning

Chip tuning – https://en.wikipedia.org/wiki/Chip_tuning

Remapping (remapare) – https://en.wikipedia.org/wiki/Remapping

ECU (calculator motor) – https://en.wikipedia.org/wiki/Engine_control_unit

Turbocharger (turbina)– https://en.wikipedia.org/wiki/Turbocharger

EGR (sistem de recirculare a gazelor de evacuare) – https://en.wikipedia.org/wiki/Exhaust_gas_recirculation

http://www.e-automobile.ro/categorie-motor/20-general/42-egr-motor.html

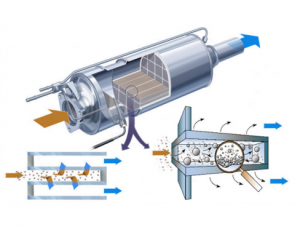

DPF (filtru de particule) – https://en.wikipedia.org/wiki/Diesel_particulate_filter

http://www.anularedpf.ro/

Soot (funingine) – https://en.wikipedia.org/wiki/Soot

DTC / P-Codes (erori ) – https://en.wikipedia.org/wiki/OBD-II_PIDs

Scan tool (instrument de scant erori / diagnoza) – https://en.wikipedia.org/wiki/Scan_tool_(automotive)

OBD (conector de diagnoza) – https://en.wikipedia.org/wiki/On-board_diagnostics / http://www.e-automobile.ro/categorie-diagnoza/5-obd-diagnoza-auto.html

BDM (programare ECU) – https://en.wikipedia.org/wiki/Background_debug_mode_interface

EEPROM (memorie interna ECU)- https://en.wikipedia.org/wiki/EEPROM

Dyno (stand dinamometric de masurare cuplu & putere) – https://en.wikipedia.org/wiki/Dynamometer#Chassis_dynamometer_.28rolling_road.29

Chiptuning - Reality, Myths and Everything In-between EN

Chip Tuning – The Reality, The Myths and Everything In-between

In this section we hope to dispel the myth/ignorance that have been instilled into many chip tuners. The resulting information is plain engineering fact and direct experience of the combined 50 years trade and formal education in our trade.

Contents

[hide]

- 1 Custom Tuning Files

- 1.1 Statistical elements

- 1.2 Curve

- 1.3 Map

- 2 Diesel Tuning / DPF Removal and Smoke Emissions

- 3 Rolling Roads: THE FACTS

- 3.1 HEAT SOAK

- 3.2 PEAK FIGURES

- 4 EGR Valve Removal, The Plain Facts

- 5 Gasoline / Petrol Stage 1234+ Tuning

- 6 ECO Tuning and Driving Style Changes

- 7 Clone / Copied Tools

Custom Tuning Files

Fact – In chip tuning there is no such thing or ever was..

For any formally qualified automotive/calibration engineer the custom remap debate is amusing to say the least for a number of reasons;

Firstly – After 2004 most engine management systems became a closed looped torque based model simply put, the engine management is adapting (optimizing) the tune of the engine in almost real time based on the hard code or what is known as the statistical dynamics element of the memory. A quality remapping engineer understands and respects this and simply enters the correct desired targets in the correct places to the code and the system references the sensors accordant (closed loop or PID) thus using these settings to achieve the desired result. The one and only time a ‘custom’ strategy is required is when a vehicle is modified to a point where the dynamics employed by the factory ECU are no longer valid for example – a larger turbo is fitted requiring new PID loops to be employed.

“Even under these circumstances, only a small modification is required to a base calculation within the ECU to correct the internal equation.”

Think of an ECU in its simplest form, it’s a calculator programmed to receive values in terms of voltages and frequencies at a rate of 1 to 200 HZ or in layman’s terms 1 to 200 times a second dependent on the type of value it needs to sample. For example – sensor values such as coolant temperature, are a slow changing value, so a sample of 1-5 HZ is fine. Where fast changing variable’s such as manifold pressure, It requires a faster sample rate of say 50 HZ or 50 times a second. The processor then first of all references (for the sake of this explanation) three memory models within the ECU, one known as ‘statistical elements’ and the others as we know them as ‘maps’ and ‘curves’

Statistical elements

This is the core structure of the ECU function – It can be made up by a number of control algorithms such as ‘Motronic’ and elemental rules such as ideal gas law, this also includes configuration switches and curve/map address library for the controller to switch between based on the strategy or mode required.

Curve

The curve structures in the ECU are a vital and are often mistaken as torque limiters by ‘CUSTOM MAPPERS’ or re-scaled in a effort to bypass a mechanical limit resulting in a loss of resolution and refinement. An ECU can only interpret what a engine is doing by its input signals via the relevant sensors. This is usually done by voltage or frequency – so the ‘curve’ is the real world signal conversion to a digital value the ECU can use in a calculation to out put to its PWM’s

Map

Basically a data matrix, a table of data values arbitrated to a output of the ECU drivers or PWM’s referencing values such as requested torque, boost, lambda and air flow. These are desired targets based on the data and control logic influenced by the ‘curve’ and ‘statistical elements’. ALL employing PID control – understanding this will expose the ignorance of most chip tuners.

Advanced ECU Engineering Principles

Diesel Tuning / DPF Removal and Smoke Emissions

No Smoke No Poke

Basic engineering fact – Smoke is WASTED energy This is the product of a badly written calibration, by normally adding fuel because its the easy and quick map to find with absolutely no recognition to thermodynamic principles,stoichiometry or Volumetric efficiency. A correctly written calibration will provide the cylinder with the correct amount of air to completely combust the given fuel. PLEASE understand that fuel is fixed sum (energy) for the ECU and air is variable, an engine is driven by the heating of air to gain the most power you must heat as much volume of air as possible from a relative due point (exothermic reaction), the fuel already in cylinder must be burnt completely to extract the most energy (allowing for the boundary layer), a complete burn of fixed fuel = more heat, more heat = more power, basic physics.

Manufacturers go to huge lengths to achieve the perfect/maximum thermal efficiency in engine design striking the perfect balance from a induction temperature and the heating point of the fuel vs permissible exhaust temperature (EGT) whist targeting the idea push/pumping(expansion) cycle or adiabatic process. The problem in tuning a diesel engine for a manufacturer is purely down to controlling EGT relative to particle matter and Nox (nitrogen oxide) emissions the very reason forcing the use of DPF systems.

So how is the damage done? By modifying the lambda (fuel relative to air) the first issue is the over loading of the DPF management cycle as the filter is designed to handle a certain amount of matter vs measured flow vs a oil quality / engine ageing strategy, think of it like this – tuning an engine, it is a given performance air filters, they provide more airflow by using better, more expensive materials.

Currently there is no material solution for DPF to achieve performance increase other than (at best) an increase regeneration cycles to keep flow optimized resulting in increased fuel use for such a regeneration leading to the inevitable shorted life cycle. So adding fuel = Dead DPF.

Turbochargers suffer greatly from tuning ignorance, and are a fundamental component in managing the efficiency of a engine. The compressor map of a turbo dictates the dynamics of the air heating process with the cylinder temperatures vs EGT calibrated precisely known as the ‘flame wall’ as diesel fuel ignition timing is dictated by the mass vs relative fuel temperature respecting thermodynamic variables / e.g. – the fuel pressure (endothermic reaction), fuel mass (duration), start of injection (timing).

We see issues with calibrations where the mass (duration) is modified, the SOI (timing) is modified along with increased rail pressure resulting in the movement of the flame wall causing a cascade rise in EGT, thus damaging the turbocharger due to the paradox of increased boost pressure only compounding the issue. Another issue born out of over fuelling and flame de-tuning is the sooting of the exhaust wheel of the turbo causing an imbalance of the turbine and jamming of the variable geometry setup where applicable, thus greatly reducing the life of the turbocharger.

Drive line and chassis harmonics – Manufacturers again go to huge length to control engine running frequency and this ‘noise’ causes long term damage to components. A simple example is the presence of a dual mass flywheel, which is tasked in part to countering this issue in conjunction with tuned engine mounts and phased injection strategies.

- By not respecting these components in a calibration, all will lead to early failure.

The work is already done in the ECU to increase the performance to a sensible point without compromising the power train. The key is understanding the physics on which the calibration was designed, so the next time you see a youtube video of a vehicle pumping a dyno cell full of black smoke think about what you have read here and the ignorance of some tuners.

Rolling Roads (Dyno): THE FACTS

Rolling roads (Dyno) are a way to measure the power of a vehicle. However, they can also lead to many an unhappy and confused car owner as results can often be misread due to a general lack of understanding of the limitations, drawbacks and also benefits of a rolling road.

There are a few fundamental things you should know about rolling roads:

- It is impossible for a rolling road to simulate real world driving. Rolling roads provide linear load on the engine and do so with a slow pull from low RPM’s to redline. It can take up to 45 seconds to reach redline. This amount of time and constant load on an engine and turbo charger will inevitably raise intake temperatures well beyond what the real world driving will see.

- Raised intake temperatures will cause the ECU to factor the boost / fuel / timing maps to reduce load, thus limiting power. This is a protection feature.

- It is very common for a car to have less rolling road performance and yet maintain strong power on the tarmac. This can be attributed to several factors.

- The fan we usually see in front of the vehicle when a vehicle is on the rollers is providing a linear flow of air (constant flow/volume/temp), usually to a small portion of the frontal area of the vehicle. If we were to compare this to real world conditions, we can prove airflow is proportionately increased as speed is increased. This isn’t replicated with the airflow on a dyno. This causes the air intake temperature to be well outside of what we would see if we were to log temperature on the road. The higher these temperatures get, the lower power output will be. So from this we can make some assumption that a car will probably make more power on the road than the dyno.

- The final figure will also be variable with weather. Ever noticed on a cool, damp evening your car seems faster??

HEAT SOAK

A term used when an engine doesn’t get adequate cooling for the given running conditions and the ECU will be forced to compensate for the additional heat. When a car suffers from heat-soak the ECU will typically go into an Exhaust Gas Temperature protection mode; lowering the requested load and increasing the amount of fuel in attempt to cool things down, this results in the curve tailing off much quicker than expected and a lower than realistic power output.

- The majority of rolling roads will load a vehicle up during a power run in a certain way, this can vastly effect how the car ‘behaves’ on the rolling road as the ECUs are load based. All requests to the engine are calculated based on the feedback the ECU has from the engine and the load it’s under.

- This doesn’t even take into account any potential issues that could be inherent with a car, the amount of heat already in the car before it goes on the rollers, or any inconsistencies between operators and rolling road calibration. For Example: vehicle weight, number of cylinders, transmission type, air temp, air pressure. All factors not entered into the dyno software correctly that can lead to BS figures.

- Wheel and flywheel figures can be a source of confusion, and there’s a danger of back-calculating flywheel figures from a chassis dyno. Power at the wheels is more meaningful and fairly accurate so long as the ambient and intake temps are reasonable. Certain rolling roads calculate force applied at the rollers, everything from there on is a mathematical equation and as such don’t necessarily give you accurate figures.

- One of the biggest mistakes people make is to take a figure from a Rolling Road as gospel. There are so many varying factors between different dynos that can affect the output, (as mentioned above), that can differentiate vastly from one rolling road to the next. Realistically, a Rolling road can be a great tool to show differences from the fitment of additional hardware, but in the guise of a rolling road ‘shoot-out’ for a one off reading they are a waste of time.

“A figure or power curve only shows what the car is doing on that dyno, on that day, in those conditions.”

- Using a Rolling Road to show the difference between cars or show the increase from software can also be unrealistic without correct preparation. If you have two identical cars running the same quality fuel, tyre pressures, etc. you can still have a variable within the ECU due to differing driving styles and conditions the cars see. One car might have been used much more aggressively than the other and have a much larger correctional factor due to adaptation from excessive heat. This can vastly affect the power output of a vehicle. Something else to be aware of is after programming an ECU the car will take a certain period of driving time to adapt (short/long term fuel trim), this period of time is dependent on driving style and conditions.

What is important is a road test and inspection of the vehicle before it’s flashed. A full check over of the vehicle to see if there are any issues that need addressing prior to software being installed.

PEAK FIGURES

- The peak numbers you get on a rolling road are typically referred to as ‘Pub Talk’ numbers; who has the most power and torque! In reality the Peak numbers are largely irrelevant; it’s the power/torque throughout the rev range and the power delivery that’s important, the peak number gives very little indication to how capable a vehicle is or how well it drives. Unfortunately there’s a lack of understanding in the industry and still a requirement to quote peak figures?

At the end of the day peak power and torque figures are all pub talk and mean very little in real world conditions. Peak figures don’t give you any indication of drivability or even a true indication of increased performance as they ignore the power/torque curve and can’t tell you how smooth, powerful and efficient the power is delivered.

- The general consensus is the higher the number the better, numbers sell. A 300hp car sounds much better than a 280hp car! But in reality what can you tell by these numbers?

- First of all, quoted power and torque numbers are peak figures, they are the highest seen figures on a power or torque curve. They tell you what power and torque a vehicle is making on that dyno but those figures are really only useful for bragging rights. For a true indication of how a vehicle will feel and where the benefits of tuning can be seen you need to assess the power and torque curves, In the below example there are three power curves,

- Purple is stock

- Red is stage 1

- Dashed blue line is hypothetical

- On paper the dashed blue line makes the most power as it peaks nearly 10bhp higher.

- However from 2400rpm through to 6000rpm the red curve makes a lot more power.

- At 3500rpm the red curve is 50bhp more than the dashed blue curve.

- On the road, a car running the red curve (with a lower power output) would be a much quicker car.

This is a good example of how a peak number can be very deceptive and not tell the full story. You can see the difference in the area under the curves and how much more the red curve has gained throughout the rev range in comparison to the dashed blue curve

We don’t go chasing peak numbers but getting the balance between power and drivability is key.

Whilst an understanding of peak figures and power under the curve is important, it’s just as important to understand that rolling road results can and do vary and aren’t always a true representation of what a car will do in the real world.

I HOPE THIS WILL MAKE SENSE, AND YET AGAIN, TAKE OUT MORE BS FROM THE INTERNET FORUMS.

EGR Valve Removal, The Plain Facts

Its a well documented obsession of enthusiast diesel owners to remove an EGR valve or an owner with a faulty EGR valve, the want to remove it.

EGR removal in engineering terms will break down into a number of issues.

We are currently seeing tuners offering EGR deletes on vehicles equipped with LIVE DPF systems. We DO NOT offer this service for a number reasons. First of all, as part of the integral emissions system that was embedded into the software, the EGR and DPF systems work together in the regeneration process, as such we only remove EGR functions with DPF deactivation.

If the EGR system is deleted by means of duty cycle and airflow modification, this will have a negative impact on the DPF regeneration cycle. The DPF system was designed to work along side the EGR using different strategies in the passive and active regeneration process.

Gasoline / Petrol Stage 1234+ Tuning

FACT – Its a load of non-sense, its either tuned correctly or not.

Usually started from vehicle owner forums run/owned/funded by tuning companies thus pushing ‘sponsors’ — pushing the myth that every time an extra piece of hardware is installed on the engine, then a calibration adjustment is required. To a certain degree this is true when you get to high levels of modification. In the eyes of the general public, this poses a grey area between the stage 1 and 2 ++ tune calibration. On a modern torque based petrol ECU, the fitting of the following requires NO further modification;

- Full exhaust system with Decat

- Cold air intake system or air filter replacement

- Inter-cooler upgrade

- Basically anything that improves airflow and/or lowers intake temperature into and from the engine.

The truth of the matter is, a correctly calibrated ECU will be able to deal with the extra air or air at a higher relative density (cooler) thus adjusting fuel and advance trims accordingly (adaption). This is where people assume, that having all of this hardware fitted they require further adjustments.

It has should be noted that some companies offer stage 1 and 2 tunes to completely stock vehicles. After 20 years we are still waiting for some one to explain what the difference is.

The requirement for a further calibration would be hardware such as;

- Upgraded much larger turbocharger

- Upgraded injectors / fuel system

- Larger MAF or modification to run on MAP alone (Alpha N)

- Basically anything that requires re-calibrating or re-scaling from standard production sensor curve (input)

Even then how this falls in the the mythical stage scale is yet to be seen. ITS EITHER TUNED CORRECTLY OR NOT.

ECO Tuning and Driving Style Changes

Fact – A client has owned a vehicle for (X) amount of time, over that period time regardless of how the vehicle is driven the client will have a very good idea on how economical their vehicle is. They have an ECO tune as they would like to gain extra economy, driving exactly the same journeys as before the remap. Soon after they realize that the return is the same or worse and only to be told that they need to drive the vehicle in a different manor. At this stage alarm bells should be ringing as this exposes several problems.

- cover up of a poor product

- incorrectly calibrated data

- the engine is running inefficiently

An engine running more efficiently will not require different load conditions. To summarize, vehicles used daily on similar routes with a RS ECO calibration will return extra MPG under the same operating conditions.

Clone / Copied Tools

FACT – with most things in life, there will always be copies, clones, rip offs. For example DVD movies and CD Albums. When it comes to chip tuning, Yes many tools have been copied/cloned etc. A quick google search will reveal the extent of how many clone tools are a wash over the internet. As an example, try and search FGtech for the legitimate FGtechnology website, lets put it this way, its not in the top 10 results. The fact that china has gone all out on manufacture and marketing of these tools, and even to the point of starting websites with very similar names means that people very little experience in chip tuning may be duped into thinking they are buying a legitimate tool a fraction of the cost of the genuine article.

DO clones Works?

This question is very difficult to answer, as clones are clones and it will be up to the user to test. The quality of the components and construction varies. The tools cannot be used while connected to the internet, so they cannot be updated to the very latest software/firmware, some protocols may or may not work due to old or corrupt software/hardware. The best source of information on these tools is the internet, like a chip tuning forum etc, although most major chip tuning sites actually ban the talk of clone tools, as you can imagine this is quite a taboo subject.

For someone looking to start up a professional chip tuning business, then there in no compromise for a genuine tool. Genuine tools are built as the manufacturer intended, All of the protocols listed 99% of the time work, so there is no real chance of error.

The economy of the clone tool market for a professional tuner is a false one. If you take into account possible lost time/earnings and replacement of damaged ecu’s, it doesn’t take many bad jobs to be at the same expenditure that a genuine tool would cost in the first place. Where possible, always use a genuine tool.

If you require advise or would like to order a particular GENUINE tool then we will be more than happy to help.

©PCW

Basic Engineering Principles EN

Contents

- 1Open loop Vs Closed Loop Management systems

- 1CLOSED LOOP SYSTEM

- 2OPEN LOOP SYSTEM

- 3Examples of Open and Closed Loop Systems

- 4Interaction Between Engine Management Systems

- 5Hall Effect Sensors – Wheel Speed/Crank Position Sensors

- 6Magnetic Inductive Sensors – Crank Position Sensors

- 7Thermal Resistors – Engine Coolant Temperature Sensors

Open loop Vs Closed Loop Management systems

Electronic Engine Management Systems utilize two forms of management when it comes to precisely controlling an engines operation. These are known as Open Loop and Closed Loop control systems.

CLOSED LOOP SYSTEM

In a Closed Loop system the ECU sends and receives a constant stream of data from various sensors throughout the engine. These sensors include but are not limited to

1, Engine management control unit with ambient pressure sensor

2, Battery

3, Ignition switch

4, Engine management system relay

5, Cruise Control lever

6, Linear pressure sensor

7, Brake pedal and clutch pedal switches

8, Lambda sensors upstream and downstream of the converter

9, Timing sensor

10, Engine coolant temperature sensor

11, Detonation sensor

12, Turbo pressure sensor

13, Engine rpm and TDC sensor

14, Intake air temperature and pressure sensor

15, Electric fuel pump relay

- Idle Up VSV’s and Fuel Pressure Sensors – Fuel Pressure Sensors are almost exclusively fitted to racing engines for fine tuning of the injector maps. The data it receives is constantly monitored, and adjustments are made to the Injector Pulse-Widths and timing along with Spark timing to ensure the engine runs as economically as possible for road car applications.

OPEN LOOP SYSTEM

In an Open Loop system the ECU ignores the data received from many of these sensors and will simply run the engine according to a base “map” that was programmed into the ECU by the manufacturer. This ECU map is the only reference point the ECU uses when it comes to determining Injector Pulse-Widths and timing and spark timing, rather than receiving and processing inputs from all the engines’ sensors.

The advantage of operating an Open Loop system is that the engine can run on far fewer sensors and inputs to the ECU and still operate to a satisfactory level. These systems are also cheap and easy to program because the ECU doesn’t need the processing power that an ECU operating a Closed Loop system does when it has to process various sensor inputs.

Theoretically and engine running with an Open Loop engine management system can run on only a Crankshaft Position Sensor and Throttle Position Sensor, something that a solely Closed Loop system would be incapable of doing. Where Closed Loop Systems come into their own is when performance and economy are the major concern; because the ECU is receiving and processing so much useful data about exactly how every aspect of the engine is running, it can make very minute and precise adjustments to maximise performance and economy at all times.

One example of why these systems are so useful is the Knock Sensor.

- Knock Sensors are installed in the engine block close to the top of the combustion chamber, the perfect position to detect a phenomenon we call engine knock or detonation. Detonation occurs when the engine is running too much spark advance or the combustion chamber is so hot that it ignites the Air Fuel Mixture before the piston reaches the top of the cylinder. When detonation occurs the flame front attempts to push the piston back down the cylinder when it is still on the upwards stroke which then causes it to make a knocking noise.

Knock sensors produce a voltage when detonation occurs and tells the ECU. The ECU then proceeds to back the spark advance off a bit until it stops, at which point the ECU then begins to increase spark advance until detonation occurs again. The reason why ECU’s do this is because engines run most economically when they run as lean as possible and with as much spark advance as possible, so knock sensors allow us to run the engine as close to the point of detonation as possible without actually detonating.

When we utilise an Open Loop system the ECU won’t safely be able to run the engine with as much spark advance. To ensure safe engine operation and reliability the ECU will be programmed to run the engine within a safe spark advance limit at all times, rather than running just on the edge of detonation – this system is safe but will not allow the engine to run in its most economical state.

As a brief summary, Open Loop systems are cheap to install but uneconomical whereas Closed Loop systems are more complex and expensive however they offer far superior economy.

Examples of Open and Closed Loop Systems

As was previously explained, a Closed Loop system utilises various sensor inputs from throughout the engine to allow the ECU to make fine adjustments to ignition and fuelling systems during engine operation. One of the most important sensors used in Closed Loop systems is the Lambda/O2 Sensor. This sensor sits in the exhaust system, usually in the collector of the downpipe, where it can monitor the composition of the exhaust gases. The sensor looks for excessive content in the exhaust gases, when the O2 levels are too high the sensor reports this back to the ECU and the ECU then knows that the engine is running too lean. When levels drop too low then the ECU knows that the engine is running too rich and fuel is being wasted, so it then adjusts injector pulse widths accordingly.

When O2 sensors fail we often find that the engine runs far too rich or too lean, resulting in excessive fuel consumption or in the worst case scenario a full engine lean out, which then melts piston tops. To avoid a full lean out however we have an Open Loop failsafe in place; if a sensor or a set of sensors fail, the ECU reverts to a safe mode which is essentially an Open Loop management system that utilises predetermined safe fuel maps to ensure the driver can get the car to a garage safely without causing any lasting damage.

When this fuel and ignition map is implemented we can expect to see a significant rise in fuel consumption, a loss of power and on engine with Variable Valve Timing we also find a drastically lowered rev limit.

Toyota’s 2ZZ-GE engine drops the rev limit from 8200RPM to 6200RPM to ensure that the VVTL-i system isn’t activated when the ECU is unable to precisely monitor and adjust fuelling and ignition requirements. From this we can gather that modern cars actually use both Open and Closed loop systems, reverting to Open Loop when sensor failures occur. A fully Open Loop system will not rely an O2 sensor to send back fuelling information, instead it will rely on a far more basic system such as a crank position sensor or in the 4A-GE’s case, a MAP sensor, TPS, Coolant Temperature sensor and AIT sensor. The 4A-GE ECU operates on a basic predetermined fuel and ignition map that was programmed in by Toyota on the EPROM chip. This fuel map will not change and the ECU only adjusts the fuelling according to the data received from these sensors. For example the ECU will increase injector pulse widths when it notices an increase in throttle angle and a drop in manifold pressure when the butterfly valve is opened right up. Similarly, when the engine begins to run very hot due to coolant passage blockages or a broken radiator fan, the ECU then starts to enrich the fuel mixture in an attempt to reduce combustion chamber temperatures. One problem with this system is if the coolant temperature sender fails – when a wire breaks the sensor reads a very high resistance and the ECU then reads this as extremely high engine temperatures. To combat this it then massively over-fuels and the engine then cuts out due to flooding. The 4A-GE ECU does however operate a failsafe system and I have personally seen it run and drive without a MAP sensor – the most important sensor for the ECU to read from is the TPS sensor; with that disconnected the engine simply will not start. This is not to say that it ran well without a MAP sensor though, quite the opposite – the engine over-fuelled wildly and “coughed” during test drives, making power delivery extremely erratic and low.

Interaction Between Engine Management Systems

The interaction between all engine management systems in Closed Loop ECU’s is critical if we are to obtain maximum performance and economy. If we could look at an ECU’s programming easily, we would see that the ECU relies on more than just one system for best fuelling and ignition control. For example, the ECU will not be programmed so that when the TPS sensor reads 25 Degrees of Throttle Angle the injector pulse is 0.8m/s no matter what other sensors read. Instead you will find that it is reliant upon other factors such as the oxygen density flowing into the engine and the manifold pressure. If the Throttle was open by 25 degrees with 12% oxygen content to offer a 0.8m/s pulse width, you would find that the pulse width then increases when the oxygen content rises to ensure maximum power and a clean burn of fuel without leaning out from the extra oxygen content.

Another example of systems that are reliant upon each other is indeed one that I mentioned earlier – the knock sensor and the ECU’s control over the ignition timing depending upon the knock sensors’ readings. The ECU knows that it must keep the engine as close to detonation as it can without actually causing detonation, so the ECU continuously increases spark advance until the engine knocks at which point it then backs it off before it starts pushing closer towards detonation again. In conjunction with the knock sensor the ECU will also continue to monitor Coolant Temperature – remember that higher combustion chamber temperatures increase the likelihood of detonation, thus spark advance will need to be backed off to compensate for that as a more economical solution to simply dumping extra fuel in the combustion chamber.

More modern engine management systems are now ‘learning’ the drivers style of driving – for the first time the driver takes a new car out of the show room the ECU will monitor and store information regarding the RPM’s the driver likes the change gear, the RPM range the driver uses most, the throttle openings the driver uses most and generally how the driver uses the engine. The ECU then optimises itself from the data gathered to ensure maximum performance and economy to match the driver. For example, when the ECU recognises the driver using the bottom of the rev range more often with small throttle openings, suggesting low speed town driving it will adjust the Throttle Actuator.

Most modern cars use a fly-by-wire system whereby the throttle pedal isn’t directly connected to the throttle lever; instead an actuator opens and closes the throttle body butterfly valve according to the voltage produced by the potentiometer on the throttle pedal. Adaptive ECU’s that note low RPM averages will then ensure that the butterfly opens by very small amounts during town driving to make it easier for the driver to manoeuvre and drive at low speeds. This benefits cars with very large throttle bodies where it is quite difficult to move by the pedal by such small amounts so as to prevent the throttle from snatching and over revving. This is why some cars have a sport mode.

Sport mode generally ignores all data gathered about the drivers’ style and maximises engine performance at the expense of economy – the throttle response will be drastically sharpened making the car tougher to drive at low speed as the throttle is sharper and more likely to snatch away from the driver at low speeds. The suspension is also firmed up in cars with active suspension, gear changes are sped up with automatic vehicles and cars with EPAS also find that the steering is sharpened up to offer more response to the driver.

Hall Effect Sensors – Wheel Speed/Crank Position Sensors

Hall Effect sensors operate on the principles suggested by Lorentzes’ law. When we pass a current through a piece of semi-conductor and then apply a magnetic field to it at a right angle to the current, a voltage is produced by the separation of charged particles within the semi-conductor. This voltage is tiny and must be amplified, so either the sensor or ECU is fitted with an amplifier to ensure the signal can be read by the ECU which operates on signal voltages between 0.1V – 4.9V. We apply the Hall Effect in vehicles in the form of a crank position sensor; there is a small current applied to the semi-conductor within the sensor and the magnetic field comes from the teeth of the flywheel. As the flywheel rotates the teeth pass the sensor and trigger it because of the magnetic field they produce. There is a single tooth missing on the flywheel, so when the flywheel rotates there is one gap in the signal produced by the sensor which the ECU notes as Top Dead Centre of Cylinders 1 and 4. The problem with this system is that Hall-Effect sensors are very expensive to produce and they can only tell the ECU that both cylinders 1 and 4 are currently at TDC, however they cannot tell the ECU which one is on the compression stroke. To get around this problem we fit the camshaft with sensors to inform the ECU of the camshaft position and thus of which cylinder is due to spark.

The other problem with Hall Effect sensors is that they need to be very close to the flywheel teeth if we are to gain a strong enough voltage within the semi-conductor. If the gap increases by the smallest amount due to the sensor bracket being dislodged, the signal will weaken substantially and will eventually cut out completely leaving the ECU without a way of knowing what the crankshaft position is – for some engines this means they will not start or they will cut out mid operation. Where Hall-Effect sensors come into their own is when we consider that they produce a digital signal that doesn’t need to be converted or conditioned by a conditioner unit within the ECU. This leaves more space within the ECU for a larger processor or allows us to reduce the ECU’s size and complexity. Magnetic inductive sensors require conditioner units because they produce an analogue signal in a rounded wave-form rather than an I/O signal such as that produced by Hall-Effect Sensors.

Magnetic Inductive Sensors – Crank Position Sensors

Magnetic Inductive sensors have been in use for many years now as Crank Position Sensors and wheel speed sensors. They work in a similar way to a coil, wherein a magnetic field is passed through a coil and this induces a current within the coil. Like a Hall Effect Sensor, the Magnetic Inductive sensor relies upon the magnetic field produced by the flywheel teeth cutting through the coil within the sensor to induce a current/voltage. And again like the Hall-Effect sensor, the voltage produced is very small and must be amplified to register within the ECU’s voltage range of 0.1V-4.9V. Again, this amplifier can be built into the sensor or into the ECU, although sensors with the amplifier built in do tend to be more expensive due to the tightly packed electronics.

The real advantage behind putting the amplifier pack within the ECU is to reduce the size of the sensor – sometimes packaging issues are very prominent in small cars, thus making the sensors in various places smaller not only leaves the sensor less prone to being damaged but also means it doesn’t get in the way of other components as much as a larger unit may have done. Another large advantage of magnetic inductive sensors lies in the fact that we have been using them for years – this means that they are considerably cheaper than Hall-Effect sensors. They have been manufactured for long enough and in enough vehicles that economy of scale reduced their price to a point where it makes a lot of sense to use them in road cars. Where they fall down is when we look at the signal they produce – they produce an analogue signal which requires a conditioner unit to convert it into a digital signal. This requires more electronics and more space either in the sensor or the ECU and adds to the complexity of the system. All the conditioner does is cut anything above a given voltage out to flatten the signal curve produced, thus turning it into an I/O digital signal that the ECU can be understood by the ECU.

Thermal Resistors – Engine Coolant Temperature Sensors

Thermal Resistors, commonly known as Thermistors for short, are used to measure the coolant temperature within an engine. These sensors report back the coolant temperature to the ECU in a form of a voltage. From the reading given by the CTS the ECU can determine whether or not the engine is at correct operating temperature. Upon cold start the CTS informs the ECU that the engine is well below operating temperature, at which point the ECU enters Open Loop mode whereby the O2 sensor is ‘ignored’ as is the EGT (Exhaust Gas Temperature) sensor. The ECU activates the Cold Start Injector to add more fuel into the combustion chambers thus warming the engine up faster. The O2 sensor and EGT Sensor are left out of the ECU’s inputs during cold start because the ECU knows they will read very low EGT’s and very high emissions, telling the ECU to reduce fuelling which then results in an engine that takes far too long to warm up. When the CTS informs the ECU that the engine is approaching correct operating temperature the ECU cuts the cold start injector out and allows the engine to run on the standard injectors. Its then enters Closed Loop mode and reintroduces the inputs from the O2 and EGT sensors to relay information regarding engine operation and emissions. At this point the engine runs as efficiently as possible and emissions are as low as possible because the ECU is now making all the minute adjustments to ensure the best economy and performance. CTS’s are a semi-conductor based sensor that changes voltage as the resistance changes within the semi-conductor. As the coolant temperature changes so does the resistance within the semi-conductor, thus altering the voltage output to the ECU. There are two forms of CTS; Positive Temperature Coefficient and Negative Temperature Coefficient. PTC’s increase in resistance as the temperature rises whereas NTC’s decrease resistance as the temperature rises. The most common form of Thermistor is the PTC. Whether a Thermistor is a PTC or and NTC is determined by the semi-conductor material used. Thermistors generally have a temperature range between -50 to 250 degrees Celsius. It is important to note that the changing resistance can only be measured if a reference voltage is supplied to the sensor. This makes the CTS an active sensor rather than a passive sensor like the Hall-Effect and Magnetic Inductive sensors that produce their own voltage. The reference voltage is supplied by the ECU, and the ECU simply compares the input voltage from the sensor with the voltage it supplies the sensor.

Advanced ECU Engineering Principles EN

Advanced ECU Engineering Principles

The cornerstone of ECU calibration is PID control, understanding this is a must in order to comprehend whats happening within any ECU.

A proportional-integral-derivative controller (PID controller) is a control loop feedback mechanism (controller) widely used in automotive and industrial control systems. A PID controller calculates an error value as the difference between a measured process variable and a desired setpoint. The controller attempts to minimize the error by adjusting the process through use of a manipulated variable.

The PID controller algorithm involves three separate constant parameters, and is accordingly sometimes called three-term control: the proportional, the integral and derivative values, denoted P, I, and D. Simply put, these values can be interpreted in terms of time: P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors, based on current rate of change. The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve, a damper, or the power supplied to a heating element.

In the absence of knowledge of the underlying process, a PID controller has historically been considered to be the best controller. By tuning the three parameters in the PID controller algorithm, the controller can provide control action designed for specific process requirements. The response of the controller can be described in terms of the responsiveness of the controller to an error, the degree to which the controller overshoots the setpoint, and the degree of system oscillation. Note that the use of the PID algorithm for control does not guarantee optimal control of the system or system stability.

Some applications may require using only one or two actions to provide the appropriate system control. This is achieved by setting the other parameters to zero. A PID controller will be called a PI, PD, P or I controller in the absence of the respective control actions. PI controllers are fairly common, since derivative action is sensitive to measurement noise, whereas the absence of an integral term may prevent the system from reaching its target value due to the control action.

Contents

[hide]

- 1 Control loop basics

- 2 PID controller theory

- 2.1 Proportional term

- 2.1.1 Droop

- 2.2 Integral term

- 2.3 Derivative term

- 2.1 Proportional term

- 3 Loop tuning

- 3.1 Stability

- 3.2 Optimum behavior

- 3.3 Overview of methods

- 3.4 Manual tuning

- 3.5 Ziegler–Nichols method

- 3.6 PID tuning software

- 4 Limitations of PID control

- 4.1 Linearity

- 4.2 Noise in derivative

- 5 Modifications to the PID algorithm

- 5.1 Integral windup

- 5.2 Overshooting from known disturbances

- 5.3 PI controller

- 5.4 Deadband

- 5.5 Set Point step change

- 5.6 Feed-forward

- 5.7 Bumpless Operation

- 5.8 Other improvements

- 6 Cascade control

Control loop basics

A familiar example of a control loop is the action taken when adjusting hot and cold faucets to fill a container with water at a desired temperature by mixing hot and cold water. The person touches the water in the container as it fills to sense its temperature. Based on this feedback they perform a control action by adjusting the hot and cold faucets until the temperature stabilizes as desired.

The sensed water temperature is the process variable (PV). The desired temperature is called the setpoint (SP). The input to the process (the water valve position), and the output of the PID controller, is called the manipulated variable (MV) or the control variable (CV). The difference between the temperature measurement and the setpoint is the error (e) and quantifies whether the water in the container is too hot or too cold and by how much.

After measuring the temperature (PV), and then calculating the error, the controller decides how to set the tap position (MV). The obvious method is proportional control: the tap position is set in proportion to the current error. A more complex control may include derivative action. This considers the rate of temperature change also: adding extra hot water if the temperature is falling, and less on rising temperature. Finally integral action uses the average temperature in the past to detect whether the temperature of the container is settling out too low or too high and set the tap proportional to the past errors. An alternative formulation of integral action is to change the current tap position in steps proportional to the current error. Over time the steps add up (which is the discrete time equivalent to integration) the past errors.

Making a change that is too large when the error is small will lead to overshoot. If the controller were to repeatedly make changes that were too large and repeatedly overshoot the target, the output would oscillate around the setpoint in either a constant, growing, or decaying sinusoid. If the amplitude of the oscillations increase with time, the system is unstable. If they decrease, the system is stable. If the oscillations remain at a constant magnitude, the system is marginally stable.

In the interest of achieving a gradual convergence to the desired temperature (SP), the controller may damp the anticipated future oscillations by tempering its adjustments, or reducing the loop gain.

If a controller starts from a stable state with zero error (PV = SP), then further changes by the controller will be in response to changes in other measured or unmeasured inputs to the process that affect the process, and hence the PV. Variables that affect the process other than the MV are known as disturbances. Generally controllers are used to reject disturbances and to implement setpoint changes. Changes in feedwater temperature constitute a disturbance to the faucet temperature control process.

In theory, a controller can be used to control any process which has a measurable output (PV), a known ideal value for that output (SP) and an input to the process (MV) that will affect the relevant PV. Controllers are used in industry to regulate temperature, pressure, force, feed, flow rate, chemical composition, weight, position, speed and practically every other variable for which a measurement exists.

PID controller theory

The PID control scheme is named after its three correcting terms, whose sum constitutes the manipulated variable (MV). The proportional, integral, and derivative terms are summed to calculate the output of the PID controller. Defining <math>u(t)</math> as the controller output, the final form of the PID algorithm is:

![]()

where

: Proportional gain, a tuning parameter

: Proportional gain, a tuning parameter : Integral gain, a tuning parameter

: Integral gain, a tuning parameter : Derivative gain, a tuning parameter

: Derivative gain, a tuning parameter : Error

: Error

: Time or instantaneous time (the present)

: Time or instantaneous time (the present) : Variable of integration; takes on values from time 0 to the present <math>t</math>.

: Variable of integration; takes on values from time 0 to the present <math>t</math>.

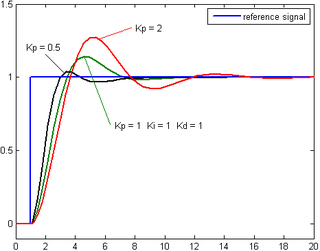

Proportional term

The proportional term produces an output value that is proportional to the current error value. The proportional response can be adjusted by multiplying the error by a constant Kp, called the proportional gain constant.

The proportional term is given by: ![]()

A high proportional gain results in a large change in the output for a given change in the error. If the proportional gain is too high, the system can become unstable (see the section on loop tuning). In contrast, a small gain results in a small output response to a large input error, and a less responsive or less sensitive controller. If the proportional gain is too low, the control action may be too small when responding to system disturbances. Tuning theory and industrial practice indicate that the proportional term should contribute the bulk of the output change.Template:Citation needed

Droop

Because a non-zero error is required to drive it, a proportional controller generally operates with a steady-state error, referred to as droop.The only exception is where the target value is the same as the value obtained when the proportional gain is equal to zero. Droop is proportional to the process gain and inversely proportional to proportional gain. Droop may be mitigated by adding a compensating bias term to the setpoint or output, or corrected dynamically by adding an integral term. Note that this term is also referred to as Offset.

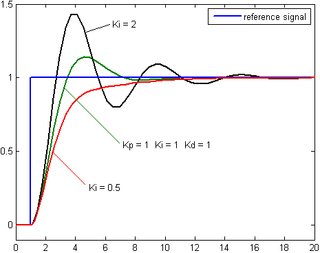

Integral term

The contribution from the integral term is proportional to both the magnitude of the error and the duration of the error. The integral in a PID controller is the sum of the instantaneous error over time and gives the accumulated offset that should have been corrected previously. The accumulated error is then multiplied by the integral gain (<math>K_i</math>) and added to the controller output.

The integral term is given by:

![]()

The integral term accelerates the movement of the process towards setpoint and eliminates the residual steady-state error that occurs with a pure proportional controller. However, since the integral term responds to accumulated errors from the past, it can cause the present value to overshoot the setpoint value (see the section on loop tuning).

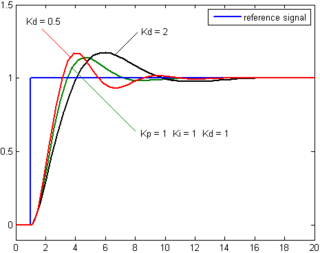

Derivative term

The derivative of the process error is calculated by determining the slope of the error over time and multiplying this rate of change by the derivative gain Kd. The magnitude of the contribution of the derivative term to the overall control action is termed the derivative gain, Kd.

The derivative term is given by:

![]()

Derivative action predicts system behavior and thus improves settling time and stability of the system. An ideal derivative is not causal, so that implementations of PID controllers include an additional low pass filtering for the derivative term, to limit the high frequency gain and noise. Derivative action is seldom used in practice though – by one estimate in only 20% of deployed controllers – because of its variable impact on system stability in real-world applications.

Loop tuning

Tuning a control loop is the adjustment of its control parameters (proportional band/gain, integral gain/reset, derivative gain/rate) to the optimum values for the desired control response. Stability (no unbounded oscillation) is a basic requirement, but beyond that, different systems have different behavior, different applications have different requirements, and requirements may conflict with one another.

PID tuning is a difficult problem, even though there are only three parameters and in principle is simple to describe, because it must satisfy complex criteria within the limitations of PID control. There are accordingly various methods for loop tuning, and more sophisticated techniques are the subject of patents; this section describes some traditional manual methods for loop tuning.

Designing and tuning a PID controller appears to be conceptually intuitive, but can be hard in practice, if multiple (and often conflicting) objectives such as short transient and high stability are to be achieved. PID controllers often provide acceptable control using default tunings, but performance can generally be improved by careful tuning, and performance may be unacceptable with poor tuning. Usually, initial designs need to be adjusted repeatedly through computer simulations until the closed-loop system performs or compromises as desired.

Some processes have a degree of nonlinearity and so parameters that work well at full-load conditions don’t work when the process is starting up from no-load; this can be corrected by gain scheduling (using different parameters in different operating regions).

Stability

If the PID controller parameters (the gains of the proportional, integral and derivative terms) are chosen incorrectly, the controlled process input can be unstable, i.e., its output diverges, with or without oscillation, and is limited only by saturation or mechanical breakage. Instability is caused by excess gain, particularly in the presence of significant lag.

Generally, stabilization of response is required and the process must not oscillate for any combination of process conditions and setpoints, though sometimes marginal stability (bounded oscillation) is acceptable or desired.

Optimum behavior

The optimum behavior on a process change or setpoint change varies depending on the application.

Two basic requirements are regulation (disturbance rejection – staying at a given setpoint) and command tracking (implementing setpoint changes) – these refer to how well the controlled variable tracks the desired value. Specific criteria for command tracking include rise time and settling time. Some processes must not allow an overshoot of the process variable beyond the setpoint if, for example, this would be unsafe. Other processes must minimize the energy expended in reaching a new setpoint.

Overview of methods

There are several methods for tuning a PID loop. The most effective methods generally involve the development of some form of process model, then choosing P, I, and D based on the dynamic model parameters. Manual tuning methods can be relatively inefficient, particularly if the loops have response times on the order of minutes or longer.

The choice of method will depend largely on whether or not the loop can be taken “offline” for tuning, and on the response time of the system. If the system can be taken offline, the best tuning method often involves subjecting the system to a step change in input, measuring the output as a function of time, and using this response to determine the control parameters.

Manual tuning

If the system must remain online, one tuning method is to first set <math>K_i</math> and <math>K_d</math> values to zero. Increase the <math>K_p</math> until the output of the loop oscillates, then the <math>K_p</math> should be set to approximately half of that value for a “quarter amplitude decay” type response. Then increase <math>K_i</math> until any offset is corrected in sufficient time for the process. However, too much <math>K_i</math> will cause instability. Finally, increase <math>K_d</math>, if required, until the loop is acceptably quick to reach its reference after a load disturbance. However, too much <math>K_d</math> will cause excessive response and overshoot. A fast PID loop tuning usually overshoots slightly to reach the setpoint more quickly; however, some systems cannot accept overshoot, in which case an over-damped closed-loop system is required, which will require a <math>K_p</math> setting significantly less than half that of the <math>K_p</math> setting that was causing oscillation.

Ziegler–Nichols method

Template:Details

Another heuristic tuning method is formally known as the Ziegler–Nichols method, introduced by John G. Ziegler and Nathaniel B. Nichols in the 1940s. As in the method above, the <math>K_i</math> and <math>K_d</math> gains are first set to zero. The proportional gain is increased until it reaches the ultimate gain, <math>K_u</math>, at which the output of the loop starts to oscillate. <math>K_u</math> and the oscillation period <math>P_u</math> are used to set the gains as shown:

These gains apply to the ideal, parallel form of the PID controller. When applied to the standard PID form, the integral and derivative time parameters <math>T_i</math> and <math>T_d</math> are only dependent on the oscillation period <math>P_u</math>. Please see the section “Alternative nomenclature and PID forms”.

PID tuning software

Most modern industrial facilities no longer tune loops using the manual calculation methods shown above. Instead, PID tuning and loop optimization software are used to ensure consistent results. These software packages will gather the data, develop process models, and suggest optimal tuning. Some software packages can even develop tuning by gathering data from reference changes.

Mathematical PID loop tuning induces an impulse in the system, and then uses the controlled system’s frequency response to design the PID loop values. In loops with response times of several minutes, mathematical loop tuning is recommended, because trial and error can take days just to find a stable set of loop values. Optimal values are harder to find. Some digital loop controllers offer a self-tuning feature in which very small setpoint changes are sent to the process, allowing the controller itself to calculate optimal tuning values.

Other formulas are available to tune the loop according to different performance criteria. Many patented formulas are now embedded within PID tuning software and hardware modules.

Advances in automated PID Loop Tuning software also deliver algorithms for tuning PID Loops in a dynamic or Non-Steady State (NSS) scenario. The software will model the dynamics of a process, through a disturbance, and calculate PID control parameters in response.

Limitations of PID control

While PID controllers are applicable to many control problems, and often perform satisfactorily without any improvements or only coarse tuning, they can perform poorly in some applications, and do not in general provide optimal control. The fundamental difficulty with PID control is that it is a feedback system, with constant parameters, and no direct knowledge of the process, and thus overall performance is reactive and a compromise. While PID control is the best controller in an observer without a model of the process, better performance can be obtained by overtly modeling the actor of the process without resorting to an observer.

PID controllers, when used alone, can give poor performance when the PID loop gains must be reduced so that the control system does not overshoot, oscillate or hunt about the control setpoint value. They also have difficulties in the presence of non-linearities, may trade-off regulation versus response time, do not react to changing process behavior (say, the process changes after it has warmed up), and have lag in responding to large disturbances.

The most significant improvement is to incorporate feed-forward control with knowledge about the system, and using the PID only to control error. Alternatively, PIDs can be modified in more minor ways, such as by changing the parameters (either gain scheduling in different use cases or adaptively modifying them based on performance), improving measurement (higher sampling rate, precision, and accuracy, and low-pass filtering if necessary), or cascading multiple PID controllers.

Linearity

Another problem faced with PID controllers is that they are linear, and in particular symmetric. Thus, performance of PID controllers in non-linear systems (such as HVAC systems) is variable. For example, in temperature control, a common use case is active heating (via a heating element) but passive cooling (heating off, but no cooling), so overshoot can only be corrected slowly – it cannot be forced downward. In this case the PID should be tuned to be overdamped, to prevent or reduce overshoot, though this reduces performance (it increases settling time).

Noise in derivative

A problem with the derivative term is that it amplifies higher frequency measurement or process noise that can cause large amounts of change in the output. It does this so much, that a physical controller cannot have a true derivative term, but only an approximation with limited bandwidth. It is often helpful to filter the measurements with a low-pass filter in order to remove higher-frequency noise components. As low-pass filtering and derivative control can cancel each other out, the amount of filtering is limited. So low noise instrumentation can be important. A nonlinear median filter may be used, which improves the filtering efficiency and practical performance.

Modifications to the PID algorithm

The basic PID algorithm presents some challenges in control applications that have been addressed by minor modifications to the PID form.

Integral windup

Template:Details

One common problem resulting from the ideal PID implementations is integral windup. Following a large change in setpoint the integral term can accumulate an error larger than the maximal value for the regulation variable (windup), thus the system overshoots and continues to increase until this accumulated error is unwound. This problem can be addressed by:

- Increasing the setpoint in a suitable ramp

- Disabling the integration until the PV has entered the controllable region

- Preventing the integral term from accumulating above or below pre-determined bounds

- Back-calculating the integral term to constrain the regulator output within feasible bounds.

Overshooting from known disturbances

For example, a PID loop is used to control the temperature of an electric resistance furnace where the system has stabilized. Now when the door is opened and something cold is put into the furnace the temperature drops below the setpoint. The integral function of the controller tends to compensate this error by introducing another error in the positive direction. This overshoot can be avoided by freezing of the integral function after the opening of the door for the time the control loop typically needs to reheat the furnace.

PI controller

A PI Controller (proportional-integral controller) is a special case of the PID controller in which the derivative (D) of the error is not used.

The controller output is given by

![]()

where ![]() is the error or deviation of actual measured value (PV) from the setpoint (SP).

is the error or deviation of actual measured value (PV) from the setpoint (SP). ![]() \Delta = SP – PV</math>.

\Delta = SP – PV</math>.

A PI controller can be modelled easily in software such as Simulink or Xcos using a “flow chart” box involving Laplace operators:

- <math>C=\frac{G(1+\tau s)}{\tau s}</math>

where

- <math>G = K_P</math> = proportional gain

- <math>G/\tau = K_I</math> = integral gain

Setting a value for <math>G</math> is often a trade off between decreasing overshoot and increasing settling time.

The lack of derivative action may make the system more steady in the steady state in the case of noisy data. This is because derivative action is more sensitive to higher-frequency terms in the inputs.

Without derivative action, a PI-controlled system is less responsive to real (non-noise) and relatively fast alterations in state and so the system will be slower to reach setpoint and slower to respond to perturbations than a well-tuned PID system may be.

Deadband

Many PID loops control a mechanical device (for example, a valve). Mechanical maintenance can be a major cost and wear leads to control degradation in the form of either stiction or a deadband in the mechanical response to an input signal. The rate of mechanical wear is mainly a function of how often a device is activated to make a change. Where wear is a significant concern, the PID loop may have an output deadband to reduce the frequency of activation of the output (valve). This is accomplished by modifying the controller to hold its output steady if the change would be small (within the defined deadband range). The calculated output must leave the deadband before the actual output will change.

Set Point step change

The proportional and derivative terms can produce excessive movement in the output when a system is subjected to an instantaneous step increase in the error, such as a large setpoint change. In the case of the derivative term, this is due to taking the derivative of the error, which is very large in the case of an instantaneous step change. As a result, some PID algorithms incorporate some of the following modifications:

- Set point ramping

- In this modification, the setpoint is gradually moved from its old value to a newly specified value using a linear or first order differential ramp function. This avoids the discontinuity present in a simple step change.

- Derivative of the process variable

- In this case the PID controller measures the derivative of the measured process variable (PV), rather than the derivative of the error. This quantity is always continuous (i.e., never has a step change as a result of changed setpoint). This modification is a simple case of set point weighting.

- Set point weighting

- Set point weighting uses different multipliers for the setpoint in the error in the proportional and derivative element of the controller. The error in the integral term must be the true control error to avoid steady-state control errors. These two extra parameters do not affect the response to load disturbances and measurement noise and can be tuned to improve the controller’s set point response.

Feed-forward

The control system performance can be improved by combining the feedback (or closed-loop) control of a PID controller with feed-forward (or open-loop) control. Knowledge about the system (such as the desired acceleration and inertia) can be fed forward and combined with the PID output to improve the overall system performance. The feed-forward value alone can often provide the major portion of the controller output. The PID controller primarily has to compensate whatever difference or error remains between the setpoint (SP) and the system response to the open loop control. Since the feed-forward output is not affected by the process feedback, it can never cause the control system to oscillate, thus improving the system response without affecting stability. Feed forward can be based on the setpoint and on extra measured disturbances.

For example, in most motion control systems, in order to accelerate a mechanical load under control, more force is required from the actuator. If a velocity loop PID controller is being used to control the speed of the load and command the force being applied by the actuator, then it is beneficial to take the desired instantaneous acceleration, scale that value appropriately and add it to the output of the PID velocity loop controller. This means that whenever the load is being accelerated or decelerated, a proportional amount of force is commanded from the actuator regardless of the feedback value. The PID loop in this situation uses the feedback information to change the combined output to reduce the remaining difference between the process setpoint and the feedback value. Working together, the combined open-loop feed-forward controller and closed-loop PID controller can provide a more responsive control system.

Bumpless Operation

PID controllers are often implemented with a “bumpless” initialization feature that recalculates an appropriate integral accumulator term to maintain a consistent process output through parameter changes.

Other improvements

In addition to feed-forward, PID controllers are often enhanced through methods such as PID gain scheduling (changing parameters in different operating conditions), fuzzy logic or computational verb logic.

Further practical application issues can arise from instrumentation connected to the controller. A high enough sampling rate, measurement precision, and measurement accuracy are required to achieve adequate control performance. Another new method for improvement of PID controller is to increase the degree of freedom by using fractional order. The order of the integrator and differentiator add increased flexibility to the controller.

Cascade control

One distinctive advantage of PID controllers is that two PID controllers can be used together to yield better dynamic performance. This is called cascaded PID control. In cascade control there are two PIDs arranged with one PID controlling the setpoint of another. A PID controller acts as outer loop controller, which controls the primary physical parameter, such as fluid level or velocity. The other controller acts as inner loop controller, which reads the output of outer loop controller as setpoint, usually controlling a more rapid changing parameter, flowrate or acceleration. It can be mathematically provenTemplate:Citation needed that the working frequency of the controller is increased and the time constant of the object is reduced by using cascaded PID controllers.

For example, a temperature-controlled circulating bath has two PID controllers in cascade, each with its own thermocouple temperature sensor. The outer controller controls the temperature of the water using a thermocouple located far from the heater where it accurately reads the temperature of the bulk of the water. The error term of this PID controller is the difference between the desired bath temperature and measured temperature. Instead of controlling the heater directly, the outer PID controller sets a heater temperature goal for the inner PID controller. The inner PID controller controls the temperature of the heater using a thermocouple attached to the heater. The inner controller’s error term is the difference between this heater temperature setpoint and the measured temperature of the heater. Its output controls the actual heater to stay near this setpoint.

The proportional, integral and differential terms of the two controllers will be very different. The outer PID controller has a long time constant – all the water in the tank needs to heat up or cool down. The inner loop responds much more quickly. Each controller can be tuned to match the physics of the system it controls – heat transfer and thermal mass of the whole tank or of just the heater – giving better total response.

©PCW

Chiptuning pas cu pas

Chiptuning pas cu pas:

- Alegeti din filtru masina d-voastra : marca. model, an si motor dupa care apasati butonul “View gains”. Va aparea fereastra cu specificatiile de putere si cuplu ,originale & dupa chiptuning.

- Lasati un mesaj pe WhatsApp sau Facebook cu poza la talon / carte si ce serviciu doriti iar in cel mai scurt timp o sa fiti contactat si veti primii oferta RS Chiptuning PRO , sau sunati-ne direct.

- Starea masinii trebuie sa fie foarte buna atat din punct de vedere tehnic precum si din punct de vedere estetic. Atentie la “Acepta termenii si conditiile“!

- Primul lucru, inainte de chiptuning se va face o diagnoza & analiza in mers pentru a depista eventualele probleme si erori prezente / memorate.

- Masina va fi lasata de catre proprietar la sediul nostru bineinteles dupa ce vom raspunde / clarifica toate intrebarile. Proprietarul NU va participa / asista la procedura de Tuning inhouse! Orice problema gasita / eroare (DOAR pe motor & transmisie) va fi discutata in prealabil , si numai cu acordul proprietarului in scris se va continua procedura, bineinteles daca este cazul.

- Test RoadDyno / Dragy (extracost).

- Citire SW ECU in functie de tipul calculatorului de motor prin OBD / SERVICE MODE / BDM / BOOT mode / EEPROM.

- Modificare SW ECU : fiecare solutie pt fiecare tip de motor a fost dezvoltata & testata in prealabil si bineinteles in conditii reale intr-un test de drum + urmarire in timp; parametrizarea ECU-ului d-voastra va fi identica , pt a avea parte de performanta maxima in conditii de maxima siguranta.

- Scriere SW ECU prin OBD / SERVICE MODE / BDM / BOOT mode / EEPROM.

- Test drive.

EXPERIENCE THE POWER AND SHEER PLEASURE OF DRIVING!

STAGE 1

STAGE 1 – modificare STRICT software, in conditii de siguranta , pe componentele stock

(fara absolut nici o interventie asupra componentelor mecanice sau orice alta modificare de orice alta natura decat SW)

STAGE 2 EGR DPF

STAGE 2 = STAGE 1 + recalibrare EGR & DPF

I. Filtrul de particule #DPF

https://en.wikipedia.org/wiki/Diesel_particulate_filter

Servicii DPF:

- Diagnoza

- Programare regenerare (statica / in mers)

- Adaptare senzori DPF

- Recalibrare software

CAUZELE COMUNE ÎNCĂRCĂRII DPF

- Kilometraj mare

- Senzori DPF (presiune /temperatura) defecti care împiedică regenerarea

- Lipsa aditivului în combustibil (acolo unde este instalat) provoacă ardere incompleta

- Probleme ale motorului, de exemplu: scurgeri de la injectoare, garnituri ulei , segmenti piston, sistem turbo, EGR, etc

- DPF-ul nu se poate regenera datorită conditiilor , adică mers mult doar in oras

- Conducerea cu o viteză/turatie prea mică pe autostradă , conditiile necesare inceperii regenerarii nefiind indeplinite

Recalibrare software:

Filtrul de particule este un consumabil scump pe masina (1000 – 2000 EUR).

Durata de viata a DPF-ului este intre 120.000 si 250.000 km la majoritatea brand-urilor auto

Masina va scoate fum fara DPF ?

Nu, daca motorul are compresie buna, injectoarele si turbina functioneaza in parametrii normali .

In general fumul apare la pornirea motorului rece sau la prima accelerare dupa ce masina a circulat subturata mai mult timp in oras.

Este benefic motorului ?

+ Motorul respira mai usor

+ 5% putere extra , nu mai exista obstacole pe evacuare -> https://en.wikipedia.org/wiki/Back_pressure

– 5% reducere consum deoarece nu se va mai face regenerarea -> https://en.wikipedia.org/wiki/Diesel_particulate_filter#Regeneration

De ce si softul SW?

Este necesar pentru ca, calcualatorul motor sa nu mai intretina DPF-ul prin post injectie (regenerare), lucru daunator motorului. In scurt timp regenerarile frecvente duc la diluarea uleiului, pentru ca motorina ajunge in baia de ulei pe la segmenti, iar in mod sigur dupa acest lucru urmeaza distrugerea turbinei si a motorului. De asemenea pe langa martorul de bord aprins “check engine” masina poate intra in timpul mersului in limp mode (safe mode) si puterea va fi redusa, aparand riscul de accidente.

Deasemenea turbina poate avea de suferit datorita regenerarilor dese, temperatura mare & contrapresiunii create datorita DPF-ului blocat.

Se recomanda verificarea functionala a turbinei + schimb de ulei + filtru !!!

II. Valva EGR #EGR

https://en.wikipedia.org/wiki/Exhaust_gas_recirculation

Servicii EGR:

- Diagnoza

- Adaptare

- Recalibrare software

Motorul va ‘respira’ mai usor

Valvele + admisia vor fi curate, fara funingine si fara risc sa se infunde

Deoarece supapa EGR lucrează în mod constant cu gazele de esapament arse, acestea au în mod natural un continut ridicat de funingine. Aceste funingine din gaze cauzează acumularea de depuneri de carbon în jurul zonei de functionare a supapei care, la rândul său determină ca supapa să aibă tendinta de a se bloca în diferite pozitii. Pentru performanta maxima a motorului, supapa EGR este închisă, ceea ce creează un mediu cu buclă închisă pentru sistemul turbo si îi permite să presurizeze la nivelul maxim cerut de ECU. Un EGR problematic poate crea un mediu de buclă deschisă (ramane blocat deschis) pentru turbo deoarece are acces direct in galeria de admisie si, ca rezultat, poate provoca probleme de presiune in turbina deci reduceri uriase de putere si de economie de combustibil

Sistemul AdBlue

Sistemul AdBlue poate cauza multe probleme, fiind scump de intretinut.

La noi aveti posibilitatea de a face:

-

Diagnoza

-

Resetare & no start

-

Recalibrare Software

Pentru mai multe informatii contacati-ne.

———————————————————–

Informatii AdBlue – Sistemul de tratare a emisiilor de NOx (SCR)

https://en.wikipedia.org/wiki/Diesel_exhaust_fluid

Motoarele diesel, comparativ cu motoarele pe benzină, datorită specificului arderii amestecului aer-combustibil, produc emisii mai mari de oxizi de azot și de particule. Acestea sunt emisii poluante cu efect nociv asupra mediului înconjurător și a omului.

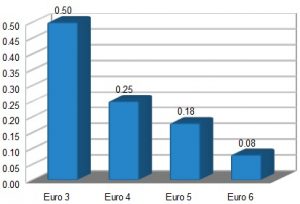

Normele de poluare au scopul de a reduce emisiile poluante ale autovehiculelor. În Uniunea Europeană norma de poluare Euro 6 va intra în vigoare de la 1 Ianuarie 2015, pentru noile modele de automobile.

Foto: Limita de emisii de NOx pentru automobile cu motoare diesel (g/km)

O caracteristică importantă a normei de poluare Euro 6 pentru motoare diesel de automobile este reducerea limitei de NOx de la 0.18 la 0.08 g/km. Pentru a îndeplini această normă motoarele diesel curente de automobile au nevoie de sisteme adiționale de post-tratare a gazelor de evacuare. Momentan sunt identificate două tehnologii care pot fi aplicate motoarelor diesel Euro 6:

- catalizator/filtru de NOx (en: NOx trap)

- sistem de injecție de uree în evacuare (AdBlue)